Philip Vaughan, a British inventor, was the first to patent the modern ball bearing. In 1794, he created the first design for a ball bearing, featuring a ball running along a groove in an axle assembly. This invention marked the first recorded use of a ball bearing in the history of mankind.

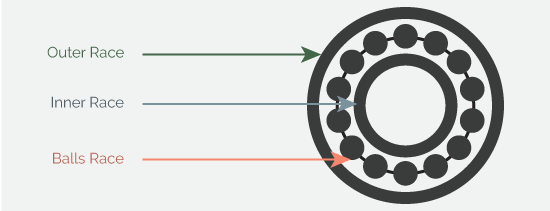

Ball bearings come in various constructions and designs, including self-aligning, thrust, and angular types. In garage door torsion assemblies, deep-groove bearings are used, featuring a flange or raised lip on the outer race which is used to mount the bearing to the plate.

The Garage Door Bearing

The garage door’s bearing is made from stainless steel. It consists of an inner race (or ring), a ball cage (or ball race), and a stationary outer race. The bearing has a 1-inch inner diameter to house and support the torsion tube. During operation, the inner race rotates, causing the balls within the bearing to also rotate.

The purpose of the balls in the ball bearing design is to minimize rotational friction, effectively reducing rolling resistance, which is the force that opposes motion. When the balls move between the races, friction is significantly reduced compared to two flat rings moving against each other.

How Many Bearings Garage Doors Have?

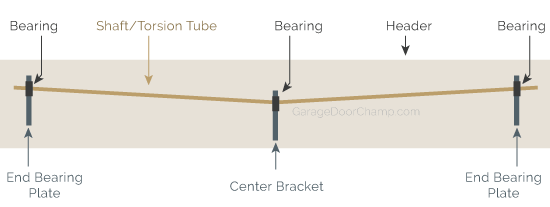

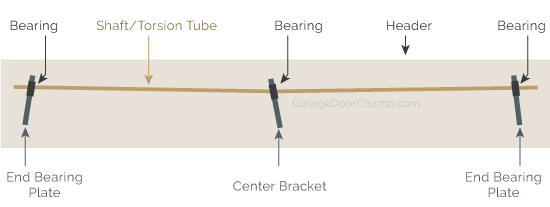

A garage door torsion system contains one bearing for each end plate and one bearing or bushing for each center bracket. A garage door bushing is a plain nylon ring that fills the gap between the garage door spring’s stationary cone and the torsion tube.

Why Do Garage Door Bearings Fail?

Garage door bearings can wear out and fail for the following reasons:

- Misalignment and faulty installation: Incorrect alignment of the torsion assembly can place excessive pressure on the bearing’s races, leading to premature failure and causing the garage door to operate abnormally or unsafely. This can increase friction and the risk of the garage door coming off the tracks. Misalignment occurs when the center bracket is not aligned with the centerline, or when the end plates are not aligned with the centerline.

- Overloaded bearings: This condition occurs when garage door bearings are subjected to excessive force or loads beyond their designed capacity. This excess load can lead to premature wear, reduced efficiency, and damage to the bearings.

- Usage: Garage door bearings can have a lifespan ranging from 5,000 to 30,000 door cycles, depending on the type of bearing.

- Improper storage: When the garage’s opening isn’t effectively sealed with proper weather stripping, it exposes the bearings to dust, humidity, moisture, and salty air (if you live near the beach). Bearings operating in high-temperature environments are also prone to premature failure.

- Improper maintenance: Although the garage door bearing isn’t designed to work at high speeds, insufficient lubrication or the use of improper lubricants can also cause the bearings to fail.

How to Maintain Garage Door Bearings?

Maintaining bearings is key for ensuring the ongoing smooth and safe operation of overhead door systems. Equally important is maintaining a clean environment and a sealed garage door to prevent contaminants from entering the bearings.

Bearings should be installed in adherence to the manufacturer’s guidelines for fits, loads, and alignments. Regular inspections help detect early signs of wear, overloading, or unusual sounds and sticking, facilitating timely repairs to prevent potential breakage. During inspections, it’s important to confirm that the torsion tube, center bracket, and end bearing plates are correctly aligned to prevent misalignment-related issues.

Understanding Misalignment of Torsion Assemblies

Misalignment is a condition in which the end bearing plates and the center bracket are not level and aligned in a straight line with each other. This misalignment places excess pressure on the torsion tube, leading to additional stress on the bearings’ races. There are two types of misalignment: Offset or parallel misalignment (fig. 1), and angular misalignment (fig. 2).

Offset or Parallel Misalignment

Offset or parallel misalignment occurs when end bearing plates and center brackets are parallel to each other but are not placed on the coplanar or same line along the rotational axis. This can occur in both the vertical plane and horizontal plane.

In Figure 1, we can see how the end bearing plates and center bracket that are mounted on different vertical planes, causing parallel misalignment and the torsion tube to have a bowed shape.

Angular Misalignment

Angular misalignment occurs when the garage door end bearing plates and center bracket are not correctly aligned at an angle to each other. In Figure 2, we can see how the end bearing plates and center bracket are slanted to the side, resulting in angular misalignment.

In both scenarios, parallel misalignment and angular misalignment lead to increased excessive pressure on the garage door torsion tube’s supporting components and the torsion tube itself. This increased pressure results in excess wear, vibration, and reduced efficiency. Additionally, the pressure leads to increased friction, which subsequently reduces the lifespan of various system components, including the garage door opener, hinges, rollers, springs, torsion tube, and bearings.

How Misalignment Affects Garage Door Bearings?

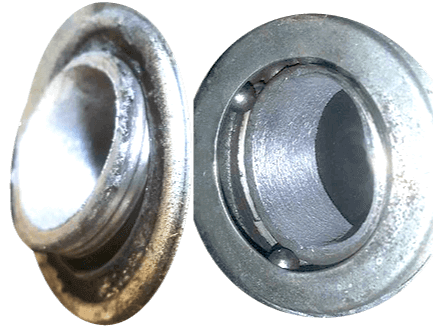

Misalignment that causes the torsion tube to bow constantly applies excessive pressure to the bearing’s balls and inner race.

Over time, the inner race may wear out and become dislodged from its position (see Fig. 3). This condition also damages the rotational direction of the bearing’s ring. Inaccurate rotation can cause the ring to grind against the torsion tube until it shears off, posing a major safety concern (see Fig. 4).

How to Replace and Align Garage Door Bearings?

Replacing or aligning garage door bearings can be a challenging task and may vary depending on the specific design of your garage door system. Here is a general outline of the steps involved:

- Start by ensuring that the garage door is fully closed. Disconnect the opener from the door using the opener’s emergency release.

- Carefully release the tension from the torsion springs, following the proper safety procedures.

- If you intend to replace the bearing, remove the end plates from their mounting points and slide them off the torsion tube, then insert the end bearing plates with the new bearing and place them in the designated spots.

- Alignment of the end plate and bearing should be performed in both the vertical and horizontal planes. Note that the end bearing plates should be straight and mounted at the same height. You can use a level if you’d like to align them vertically, though it’s not necessary. Once properly aligned, use the bolts to secure the new end plates and bearings in place, and ensure that the torsion tube is not bowed before you re-tension the springs.

- Re-tension the torsion springs to the appropriate torque level and test the balance of the garage door. Make any necessary adjustments.

Garage door repairs that require working on the springs can be hazardous without the right tools and knowledge. Therefore, if you are unsure about how to replace and align the door bearings, it’s advisable to consult a licensed garage door repair technician.

Signs That Your Bearings Need to be Replaced

There are several signs indicate that your garage door bearings may need to be replaced:

- Black powder or metal shavings accumulation around the bearing location, which is often a consequence of the grinding or wear of bearing components. This accumulation typically consists of a mixture of worn-off metal particles and debris.

- The inner bearing ring is loose or mispositioned, to the point where you can clearly see or nearly see the bearing’s balls.

- Unusual sounds and squeaking persist from the bearing, even after applying lubricant.

- Frequent repairs and issues, such as garage door cables repeatedly coming off the pulley or the door constantly coming off the tracks.

In summary, malfunctioning bearings and torsion assembly components not only create risky operating conditions but can also result in the garage door getting stuck in its position (whether open, closed, or halfway), or even coming off the tracks. When repairing, maintaining, or installing garage doors, a licensed garage door technician bears the responsibility of ensuring that the garage door’s torsion assembly is properly aligned and that the bearings are in good working order. This process guarantees safe and efficient operation, significantly extending the lifespan of the garage door and the equipment.

The wording is not appropriate by using the word pressure. Pressure is Force/unit Area. By having bearings misaligned, it places a moment or couple on the bearing itself. This creates a lateral force inside the bearing that it is NOT designed to react. Thus, you have a bearing failure within a short period of operation.