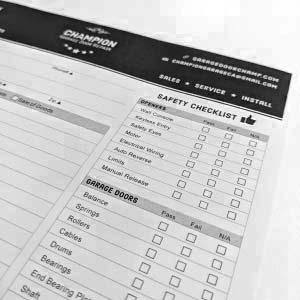

Our signature garage door maintenance, tune-up, and safety inspection service is designed to confirm compliance across our service area while identifying and addressing potential risks to the safety and reliability of the system. By promptly addressing the highest-priority equipment issues identified during inspections, we ensure an optimal level of safety and functionality.

Scheduled maintenance should occur within a designated timeframe and at regular intervals, either in accordance with manufacturer guidelines or upon customer request. This service includes preventive and remedial measures, covering both mechanical and technical aspects. The goal is to ensure the functional and structural integrity of the garage door and its mechanisms, prevent fire and electrical hazards, minimize operational risks, and ensure a satisfactory level of performance.